Thermoforming

Thermoforming - an efficient way to mould plastics

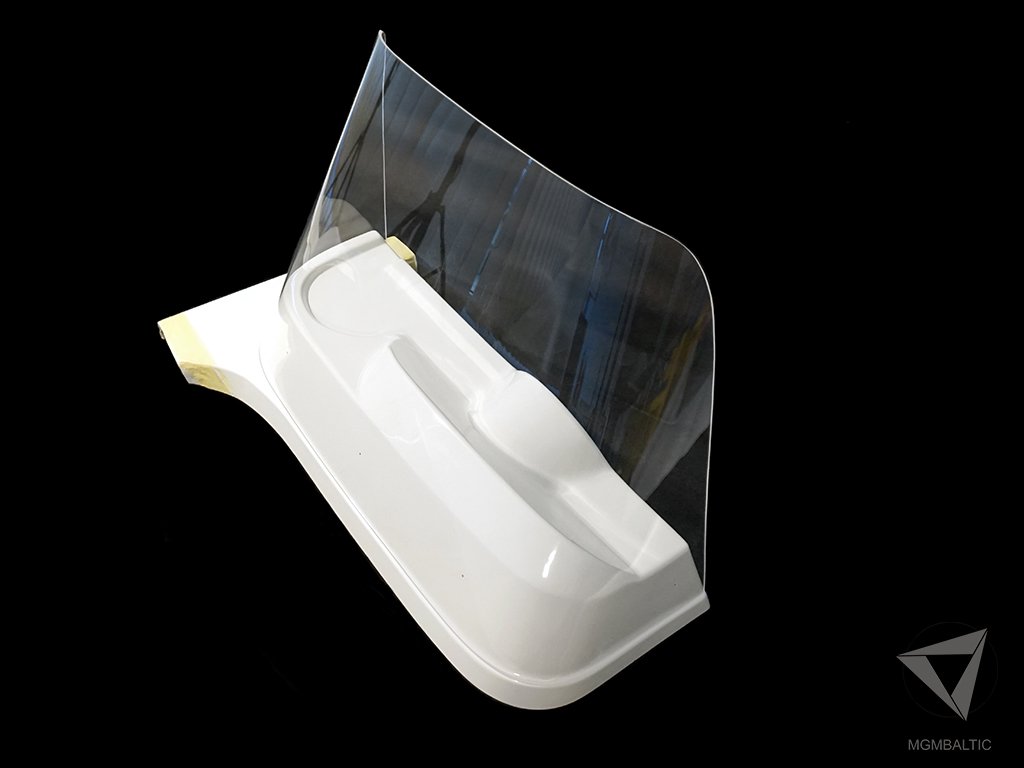

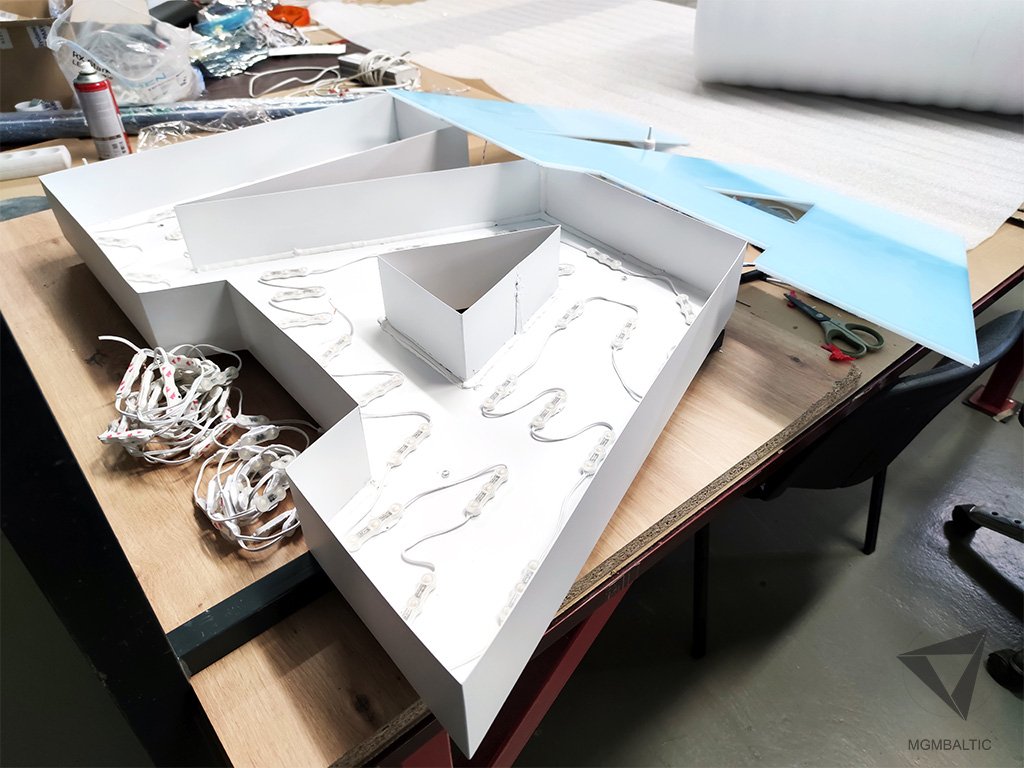

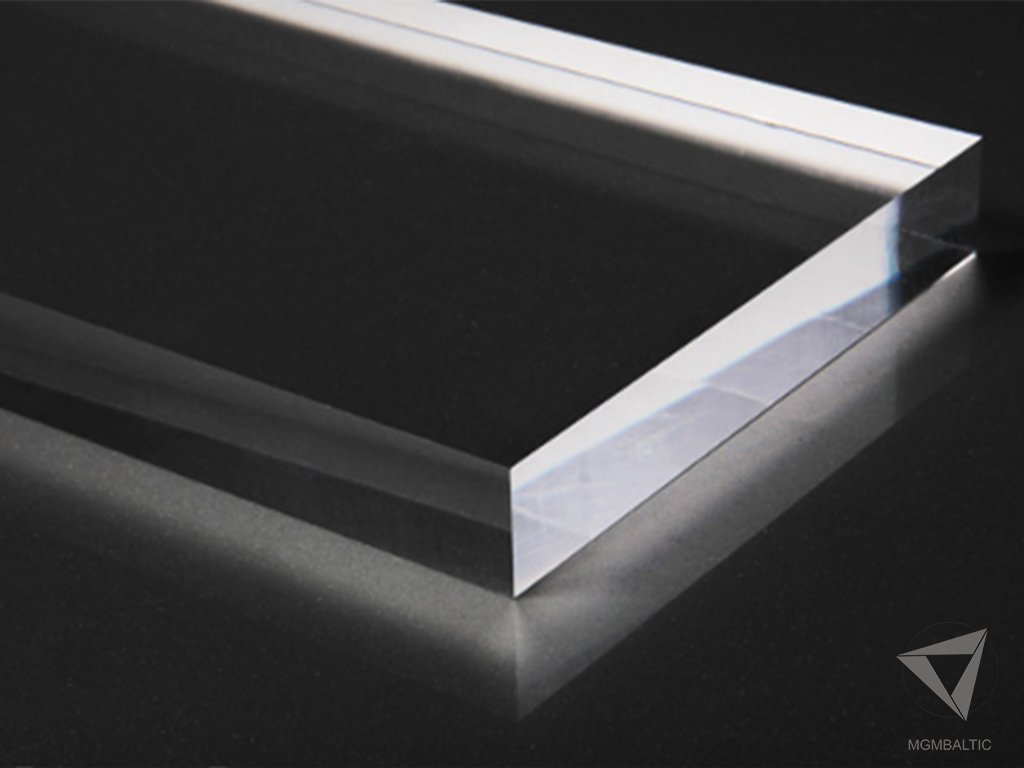

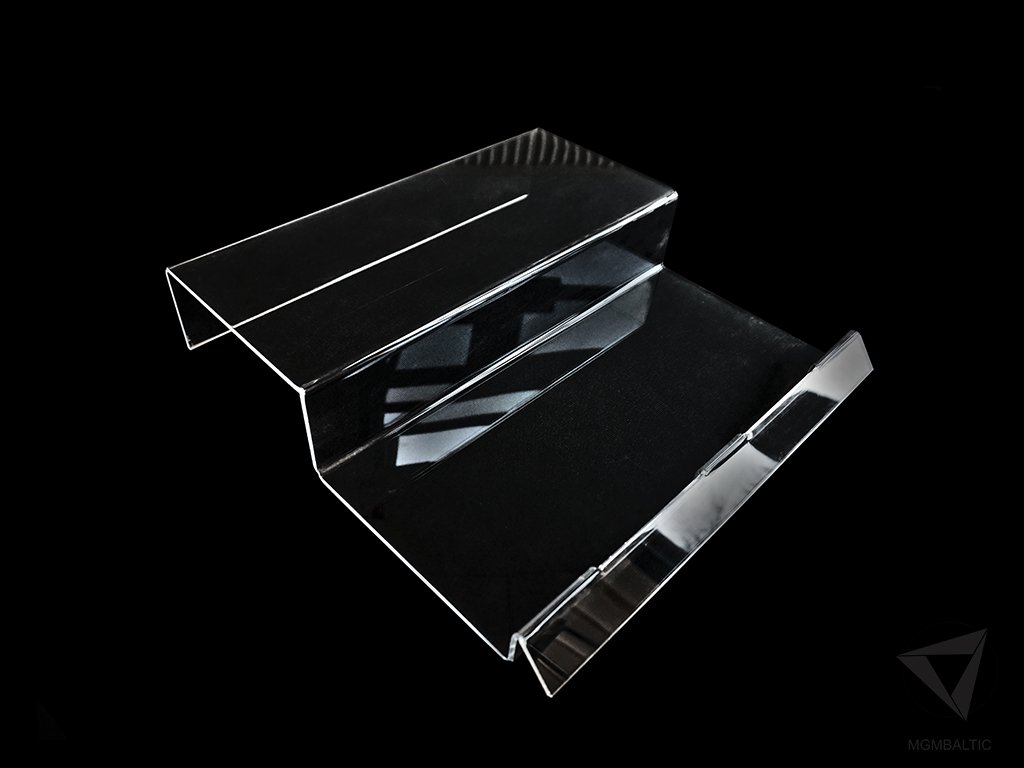

Thermoforming is a modern plastic manufacturing process where plastic sheets are heated to a certain temperature, made flexible and moulded to a specific shape. After moulding, the plastic is cooled, shaped and trimmed to fit the final design.

The main advantages of thermoforming:

- Flexibility in production – galima formuoti įvairių dydžių ir formų gaminius.

- Economic - lower production costs compared to other moulding methods.

- Quick production - short production cycles allow you to get your products to market quickly.

- High quality - accurate reproduction of detail and surface texture.

Where is thermoforming used?

- Packaging (food, medical, electronics).

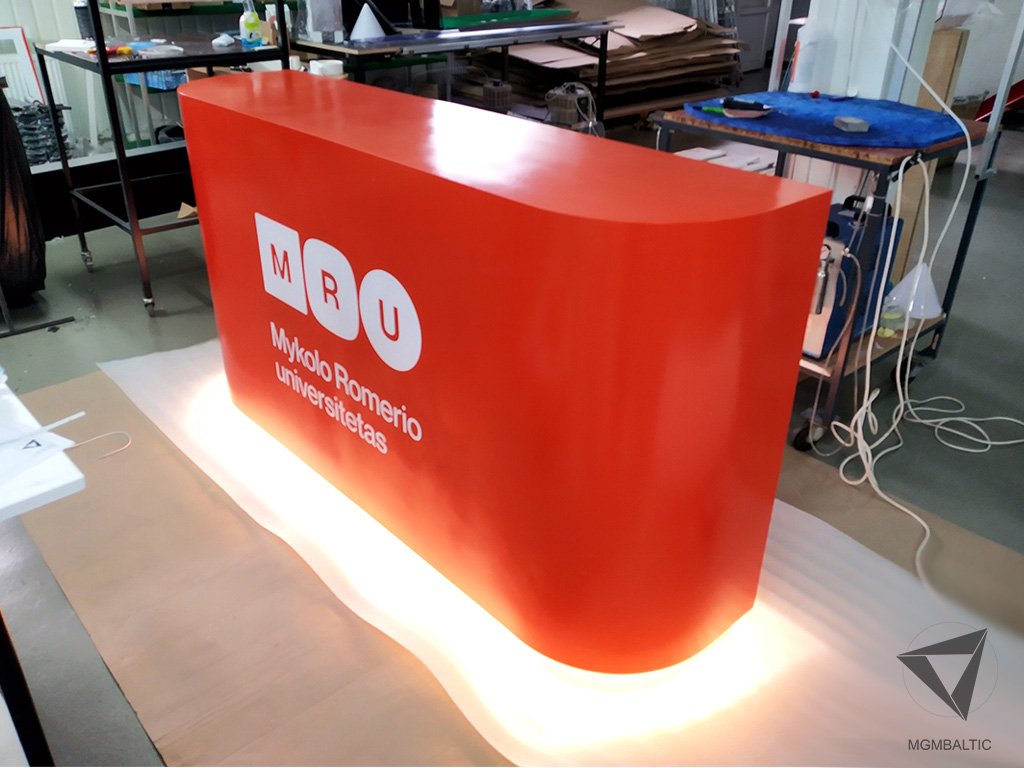

- Advertising products (billboards, stands, advertising panels).

- Automotive (interior parts, hoods).

- Medical equipment (sterile packaging, protective caps).

Thermoforming is an efficient, fast and widely applicable method of moulding plastics, allowing you to create a wide range of products to suit your individual needs.